Quality Assurance

Since 1976, we have worked on R&D and production expansion for medical-use rubber plugs and plastic medical equipment. Over the years, we have made plant improvements to achieve GMP-compliant production and quality management. Our highest-priority issues are research into the polymer materials that are optimal pharmaceuticals and medical devices, blending development and the adoption of advanced production technology, and the implementation of quality management to ensure product safety. As a company that is dedicated to operating diligently under a structure that enables us to respond immediately to customer needs.

Facility

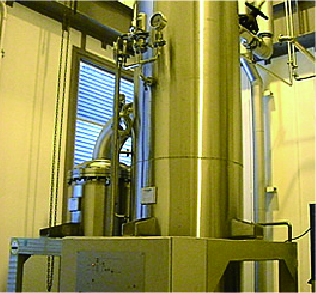

■Clean production line for medical-use rubber products

The washing of medical-use rubber plugs involves extracting and conducting pyrogen destruction processing, and then final washing is conducted by an automated washing machine. The automated washing machine uses a rubber plug stirring method driven by liquid circulation to evenly treat a large volume of rubber plugs. The washing water is filtered with a UF membrane filter to prevent foreign object adhesion to the surface of the rubber plugs, which are then dried during clean air generated using PURE STEAM as a heat source. Lastly, the rubber plugs are inspected for shipping in a clean room before being packaged.

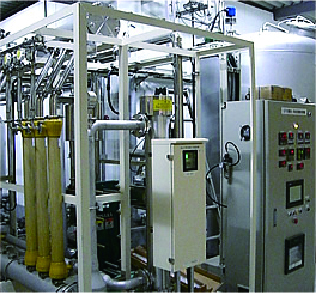

■Clean assembly plant for plastic medical products

All production of plastic medical products is conducted fully in a clean plant dedicated to the production of medical equipment, from tube extruding and forming to T-die cast raw material processing, high-frequency welding, assembly, packaging, and sterilization processes.

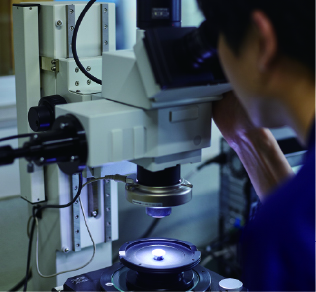

Quality management

We conduct manufacturing work in accordance with internal procedural manuals that are based on GMP standards, checking product quality with operation records, machinery, and environment records in each production process. In addition, we are equipped with various analytical instruments, including a Fourier transform infrared spectrophotometer and an atomic absorption spectrophotometer, and we have established a quality control structure that includes procedures such as fine particle testing, eluate testing, and pyrogen test.